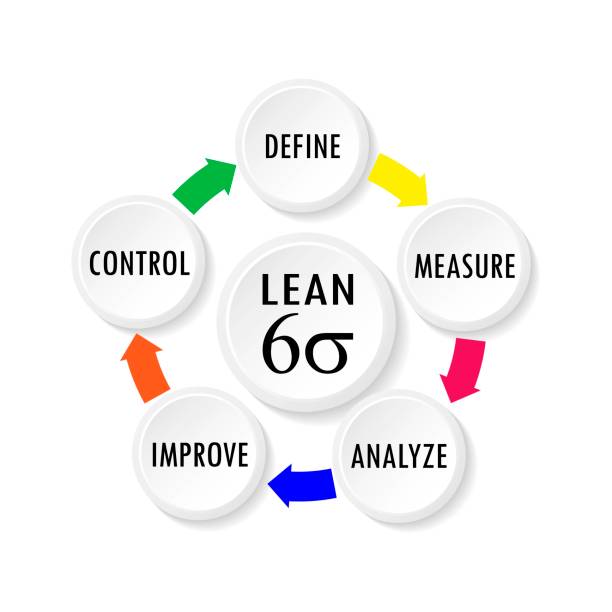

Lean Six Sigma

The Six Sigma Training Course provides a deep understanding of process improvement methodologies, quality control tools, and data-driven problem-solving techniques. This course covers Lean Six Sigma fundamentals, statistical process control, Six Sigma belts (White, Yellow, Green, Black, and Master Black Belt), and real-world case studies. Learners will gain expertise in using Six Sigma tools like Pareto Charts, Fishbone Diagrams, FMEA, and control charts to enhance business performance.

Why Choose Our Six Sigma Training?

Comprehensive Six Sigma Curriculum – Covers Lean, DMAIC, and Six Sigma tools.

Industry-Recognized Certification – Get trained by certified Six Sigma experts.

Real-World Case Studies – Apply Six Sigma in manufacturing, healthcare, IT, and business processes.

Hands-On Learning – Work with statistical tools like Minitab, Excel, and Python for Six Sigma.

Covers All Six Sigma Levels – From White & Yellow Belt to Green, Black, and Master Black Belt.

Flexible Learning Options – Choose between live instructor-led training, self-paced learning, and corporate training.

Who Should Learn Six Sigma Training?

- Quality Analysts & Process Improvement Professionals optimizing workflows.

- Operations Managers & Manufacturing Experts reducing defects & waste.

- Project Managers & Business Analysts improving project efficiency.

- IT & Software Engineers applying Six Sigma in process automation.

- Healthcare & Service Industry Professionals enhancing service quality.

- Anyone preparing for Six Sigma Certification (White, Yellow, Green, Black Belts).

What You Will Learn in Six Sigma Training

- What is Six Sigma & Why It’s Important?

- Lean vs. Six Sigma – Key Differences & Benefits

- Understanding Six Sigma Belts & Certifications

- Define – Problem Identification & Project Goals

- Measure – Data Collection & Process Mapping

- Analyze – Identifying Root Causes & Statistical Analysis

- Improve – Implementing Solutions & Process Optimization

- Control – Sustaining Improvements & Monitoring KPIs

- Pareto Charts, Fishbone Diagrams, Control Charts

- Failure Mode and Effects Analysis (FMEA)

- Statistical Process Control (SPC) & Hypothesis Testing

- Eliminating Defects & Variability in Processes

- Reducing Cycle Time & Improving Workflow Efficiency

- Using Minitab & Excel for Six Sigma Analysis

- Manufacturing – Reducing Defects & Improving Productivity

- Healthcare – Enhancing Patient Care & Reducing Errors

- IT & Software – Process Automation & Quality Assurance

- Finance & Banking – Risk Management & Fraud Prevention

- Understanding Six Sigma Certification Levels (White, Yellow, Green, Black, Master Black Belt)

- Practice Tests & Real-World Case Studies

- Exam Preparation Strategies & Mock Tests

Course Curriculum

- What is Six Sigma

- Why Six Sigma

- About Six Sigma Exam and Pre-requisites

- Enterprise-wide view

- Leadership

- Overview of Six Sigma

- Overview of DMAIC Methodology

- Impact on stakeholders

- Critical to x (CTx) requirements C -Benchmarking

- Business performance measures E -Financial measures

- Team formation

- Team facilitation

- Team dynamics

- Time management for teams E -Team decision-making tools

- Management and planning tools

- Team performance evaluation and reward

- Voice of the customer

- Project charter

- Project tracking

- Process characteristics

- Data collection

- Measurement systems

- Basic statistics

- Probability

- Process capability

- Measuring and modeling relationships between variables

- Hypothesis testing

- Failure mode and effects analysis (FMEA)

- Additional analysis methods

- Design of experiments (DOE)

- Waste elimination

- Cycle-time reduction

- Kaizen and kaizen blitz

- Theory of constraints (TOC)

- Implementation

- Risk analysis and mitigation

- Statistical process control (SPC)

- Other control tools

- Maintain controls

- Sustain improvements

- Common DFSS methodologies

- Design for X (DFX)

- Robust design and process

- Special design tools

- Linkages of Six Sigma to CMMI