CERTIFIED LEAN SIX SIGMA BLACK BELT PROGRAM

- Weekdays

- Classroom Sessions

- 3 Months

- Weekdays

- Online Sessions

- 3 Months

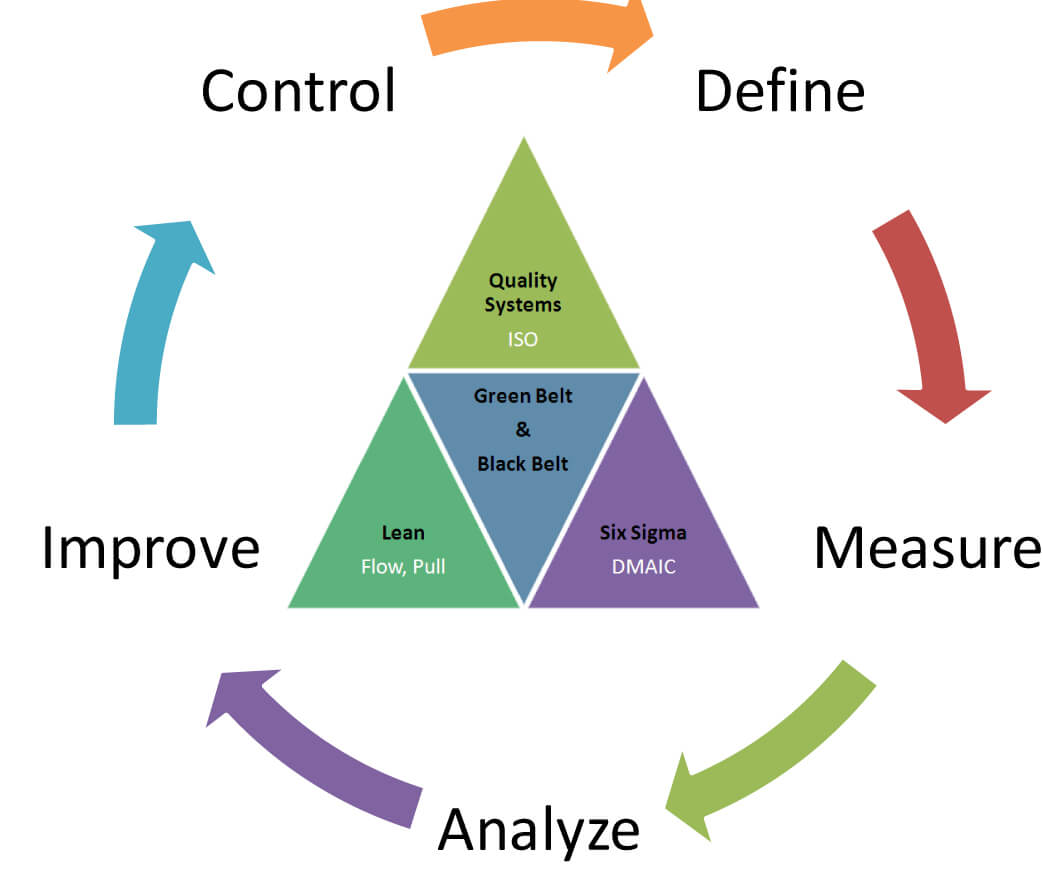

The Six Sigma Black Belt Training Course is an intensive program that covers advanced Lean Six Sigma tools, project management techniques, leadership skills, and statistical analysis. This training will prepare you to lead cross-functional teams, manage enterprise-wide process improvement projects, and drive operational excellence. Learners will gain expertise in DMAIC (Define, Measure, Analyze, Improve, Control), Design for Six Sigma (DFSS), hypothesis testing, regression analysis, and Failure Mode and Effects Analysis (FMEA).

Upon completion, participants will be prepared for the Six Sigma Black Belt certification exam and become proficient in leading high-impact process improvement initiatives across industries.

Why Choose Our Six Sigma Black Belt Training?

- Industry-Recognized Certification – Get trained by certified Six Sigma Master Black Belt professionals.

- Advanced Process Improvement Techniques – Learn strategic Six Sigma methodologies & Lean tools.

- Leadership & Project Management Skills – Develop expertise in leading high-impact Six Sigma projects.

- Hands-On Learning – Work with real-world case studies and Six Sigma applications.

- Master Statistical Analysis Tools – Use Minitab, Excel, and Python for Six Sigma.

- Flexible Learning Options – Choose between live instructor-led training, self-paced learning, and corporate training.

- Exam Preparation Support – Access mock tests, quizzes, and certification guidance.

Who Should Learn Six Sigma Black Belt Training?

- Quality Managers & Process Improvement Experts looking to enhance operational efficiency.

- Operations & Manufacturing Professionals optimizing production processes.

- Project Managers & Business Analysts leading large-scale Six Sigma projects.

- IT & Software Engineers applying Six Sigma in process automation and quality assurance.

- Healthcare & Service Industry Professionals improving patient care and service quality.

- Finance & Banking Professionals enhancing risk management and fraud prevention.

- Anyone preparing for the Six Sigma Black Belt Certification to advance their career.

What You Will Learn in Six Sigma Black Belt Training

- What is Six Sigma Black Belt & Its Role in Process Improvement?

- Key Differences Between Green Belt & Black Belt Certifications

- Leadership & Change Management in Six Sigma Projects

- Leading Cross-Functional Teams & Managing Enterprise-Wide Projects

- Strategic Decision-Making & Business Process Optimization

- Driving Organizational Change Through Lean Six Sigma

- Define – Business Problem Identification, Project Selection, & ROI Calculation

- Measure – Statistical Data Collection, Measurement System Analysis (MSA), & Process Capability Studies

- Analyze – Advanced Root Cause Analysis, Regression Analysis, & Design of Experiments (DOE)

- Improve – Implementing Solutions Using Kaizen, DFSS, & Lean Tools

- Control – Long-Term Sustainability, Control Plans, & Risk Mitigation Strategies

- Failure Mode & Effects Analysis (FMEA) & Risk Management

- Hypothesis Testing, ANOVA, Regression Analysis & Design of Experiments (DOE)

- Control Charts, Process Capability Analysis (Cp, Cpk), and Statistical Process Control (SPC)

- Manufacturing – Reducing Defects & Cycle Time Optimization

- Healthcare – Enhancing Patient Safety & Process Efficiency

- IT & Software – Process Automation & Reducing Bugs & Defects.

- Finance – Fraud Prevention & Risk Management Strategies

- Leading & Managing Six Sigma Black Belt Projects

- Case Studies & Hands-On Project Implementation

- Mock Tests & Exam Preparation for Six Sigma Black Belt Certification

Course Curriculum

- Project Scope Management

- Project Time Management

- Project Cost Management

- Stakeholder Management

- Communication Management

- Risk Management

- DMADV – Define, Measure, Analyse, Design, Verify

- IDOV – Identify, Design, Optimize, Verify

- Identify CTQs

- Creating the risk management plan

- Identify the technique used for plan risk management process

- Identify sections of risk management plan

- Recognize the principles of risk tolerance, probability and impact

- Inputs to risk planning

- Beyond customer requirements – identifying ‘‘delighters’’

- Using AHP to determine the relative importance of the CTQs

- Five Checksheets

- Seven Quality Management tools

- Measurement System Analysis

- Gage R & R

- Discrimination

- Stability

- Bias

- Repeatability

- Reproducibility

- Linearity

- Gage Study and Kappa Statistic

- Measurement Plan

- Using customer demands to make design decisions

- Using weighted CTQs in decision-making

- Pugh concept selection method

- Hypothesis Testing including both parametric & Non-parametric tests

- Mann-Whitney test

- Mood’s Median test

- Kruskal-Wallis test

- Regression techniques

- Linear Regression

- Logistic Regression

- Poisson Regression

- Binomial Regression

- Negative Binomial Regression

- Zero-Inflated Poisson / Zero-Inflated Negative Binomial Regression

- Predicting CTQ performance

- Process simulation

- Virtual DOE using simulation software

- Design phase cross-references

- Nested Designs and change variables

- Mixture Designs

- Main Effect plots and interaction plots

- Fold-over design

- Pilot run

- Pre-pilot

- Post-pilot

- Transition to full-scale operations

- Verify phase cross-references

- All aspects of control phase of DMAIC

Certification

Upon successful completion of the training, participants will receive a Course Completion Certificate from Techtroma. This certification validates your skills and knowledge in Data Science, making you industry-ready. Please note that this is not a vendor-specific certification but a recognition of your learning from Techtroma.